Corrosion & EAC in LWR environments

Austenitic stainless steels, nickel-based alloys, and their welds are widely used in light water reactor (LWR) as critical components of reactor coolant pressure boundaries (RCPB), such as primary system pipes, steam generator tubes, penetration nozzles, and so on. These components and associated welds are in contact with high-temperature and high-pressure primary system coolant, and subjected to corrosion and environmental assisted cracking (EAC) problems during operation. Corrosion and EAC susceptibility of austenitic alloys and related welds are experimentally evaluated and the corrosion produced oxides are analyzed in details using various technique to clarify the underlying mechanisms. Understanding the mechanisms of such corrosion-related degradation of structural materials in LWR environments is the crucial step to mitigate the corrosion-related damage and failure, and eventually assure the integrity and safety of nuclear power plants. NPPs, and is of great significance to ensure the long-term, safe and stable operation of NPPs. Furthermore, the in-depth understanding of the degradation mechanism regarding corrosion and EAC can be used to the new alloy development with improved corrosion and EAC resistance.

Evaluation of corrosion resistance and characterization of oxide lagers of austenitic alloys and welds

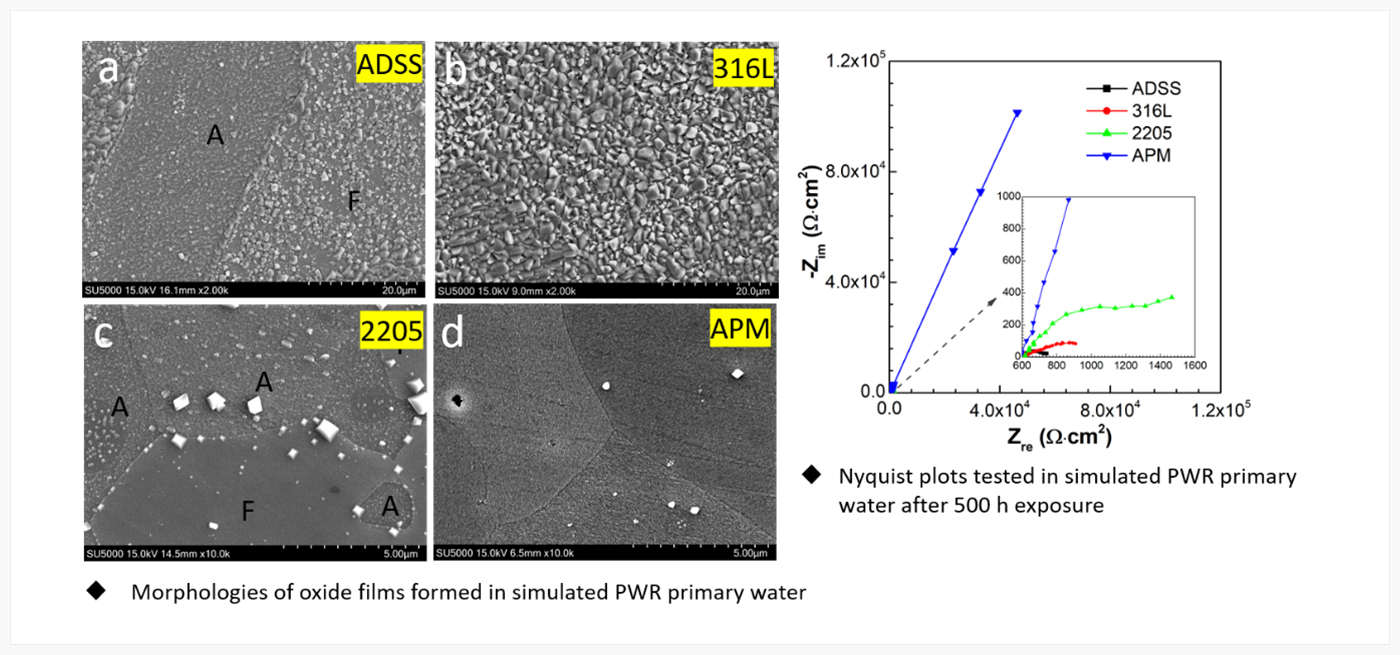

Corrosion behaviour of austenitic stainless steels, nickel-based alloys, and their welds is investigated in simulated PWR primary water environments. Typically, coupon-type specimens are immersed in the autoclave for prolonged period (up to 5,000 h). Periodically, the weight changes are measured and the oxides are analyzed. Often, water chemistry is controlled to see the effects of dissolved oxygen (DO), dissolved hydrogen (DH), and Zn-addition. The structure of oxide layers is analyzed using various electron microscopes as well as X-ray diffractometer. In addition, the electrochemical properties of oxide layer are studied using electrochemical impedance spectroscopy (EIS) and Mott-Schottky method. Recently, in-situ EIS set-up in simulated PWR water environment was installed in an autoclave, which will give more information on corrosion behaviour of the alloys. Materials of interest are Nickel-base alloys (Alloy 600, 82/182 weld, Alloy 690, 52 weld), commercial austenitic stainless steels (304(L), 316(L), 347, 310S) and associated welds, and candidate ATF alloys (FeCrAl, DSS 2205). Newly developed alloys (ADSS and AFS for ATF, ARES for internals) are also investigated.

Releated Publication

More view

Releated Publication

More view

Environmentally-Assisted Fatigue(EAF) of austenitic Alloys

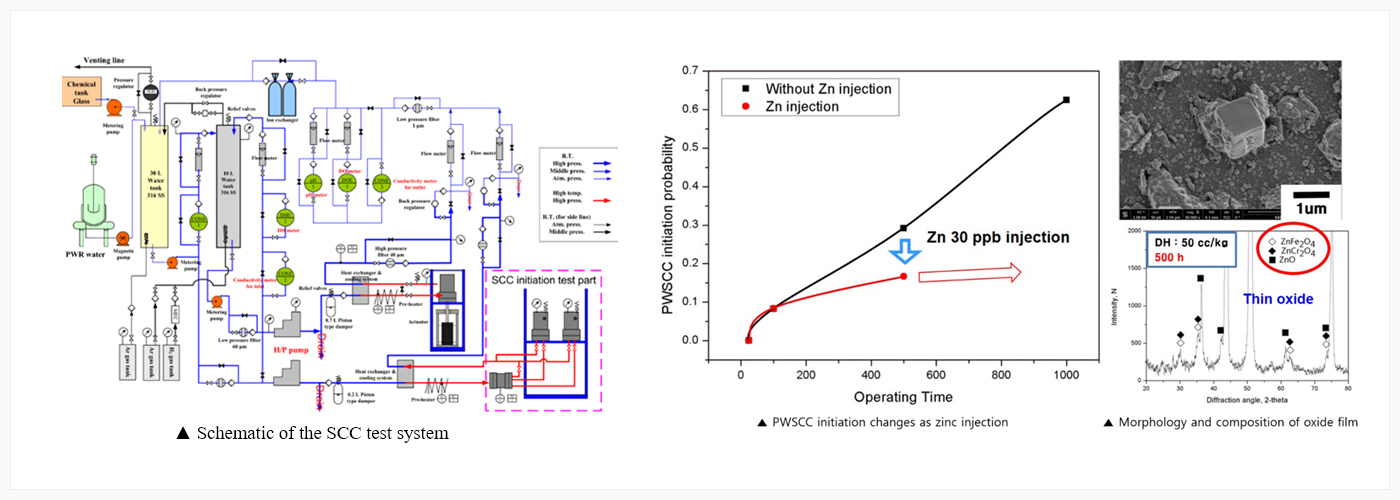

The primary water stress corrosion cracking (PWSCC), which is well known as a representative degradation of nuclear power plants (NPPs), is occurred when the vulnerable materials are exposed to corrosive environment and tensile stress is imposed. PWSCC is frequently observed for relatively low-Cr Ni-base alloys like Alloy 600 and 82/182 weld, but austenitic stainless steels are not immune. The PWSCC behavior of alloys are investigated by crack initiation test in autoclaves using various specimen loading types such as C-ring, U-bend, three-point bend, crevice bent-beam, tensile loaded specimens. The schematic of the SCC test systems is shown in Fig. 1, containing two autoclaves with recirculating loop. The SCC initiation tests are conducted at 360℃ water or 400 ℃ steam environments as accelerated test conditions. The observed initiation behaviour and oxide characterization results are compared to understand the mechanism and effect of water chemistry conditions. The effects of dissolved hydrogen (DH) content and Zn addition on PWSCC initiation behaviour are being investigated. The beneficial effect of Zn addition of PWSCC of 182 weld was confirmed by this group. Also, the PWSCC resistance of common commercial sustenitic alloys (+ associated welds) and newly developed alloys (ADSS and ARES) are studied. Recently, slow strain rate test (SSRT) set-up was added to the group, which will be used to quick and comparative studies of various alloys and water chemistry conditions.

Releated Publication

More view

Releated Publication

More view

Primary water stress corrosion cracking of austenitic alloys

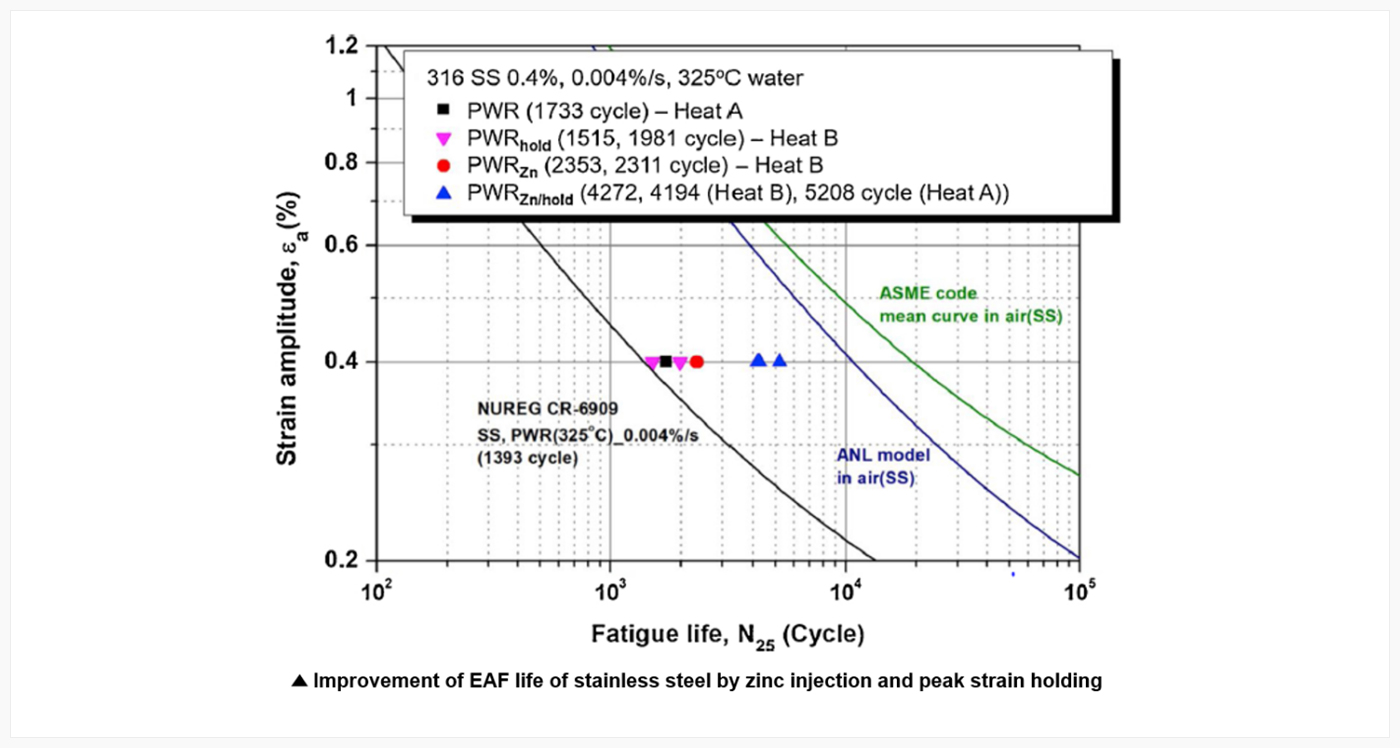

Since 1980s, lots of laboratory test of low cycle fatigue (LCF) in high temperature water simulating nuclear power plant environments (so-called environmentally-assisted fatigue, EAF) have been reported, which suggest that the current fatigue design curves in ASME Code may not be conservative enough. After much debate, the U.S. Nuclear Regulatory Commission issued the Regulatory Guidance 1.207 in 2007, which requires that environmental effect of nuclear power plants should be included in the fatigue analysis of new NPPs, and license renewal as well, later. Because of large environmental correction factors, greater than 10 in certain conditions, it becomes a significant burden to meet the fatigue design requirements. Even though there were lots of efforts to understand and improve the environmentally-assisted fatigue (EAF) behavior of structural materials of NPPs such as low alloy steels, stainless steels, and Ni-base alloys by the researchers worldwide, no clear mitigative measures have been developed. In our group, extensive EAF test have been performed over a decade and identified key mechanisms of EAF for austenitic alloy. Recently, we found that the EAF life of 316 stainless steel is significantly improved (~ factor of 3) when small amount of Zn was added to PWR water in the peak strain holding condition. Electrochemical analysis and oxide analysis results in the crack tip area also supported the test results. Currently, follow-up tests in various strain holding and Zn concentration are underway.

Releated Publication

More view

Releated Publication

More view

Evaluation of corrosion resistance for candidate ATF cladding materials

Many accident-tolerant fuel (ATF) cladding materials have been proposed to replace Zr-based alloys cladding in light water reactors after the Fukushima nuclear power plant accident. The ATF cladding materials should provide greater safety margins to lessen severe fuel degradation by avoiding or delaying cladding materials melting under severe accident conditions in LWRs. In other research groups, Cr-based coatings, SiC-based materials, FeCrAl-based alloys have been extensively studied for ATF applications. Meanwhile, this group developed high strength (YS ~ 1 GPa) alumina-forming duplex stainless steel (ADSS) alloys as ATF candidate materials, which showed satisfactory corrosion resistance in normal PWR and severe accident conditions. We are focusing on the evaluation of the corrosion behavior for ADSS alloys in the simulated PWR environment, the simulated spent fuel pool environment and Cl- containing environment, and the results are compared with several commercial stainless steels. The goal of this research is to provide a better and deeper understanding of the corrosion mechanism of various stainless steels with different composition and matrix phases, which would provide guidance for the optimization of the developed ADSS alloys.

Releated Publication

More view

Releated Publication

More view

Pitting and Chloride Induced SCC (CISCC) resistance evaluation for dry storage canister

The structural materials for the nuclear waste canister would be exposed indefinitely to saline chloride environment and it is essential for the material to maintain the structural integrity to avoid radioactive material leakage. Currently, 304(L) and 316(L) austenitic stainless steels are used considered as canister materials, and several instances of chloride induced stress corrosion cracking (CISCC) failures have been reported. The presence of residual stresses around the weld region in combination with the aggressive chloride environment make it highly susceptible to pitting corrosion and consequent CISCC failure. In our research group, we are evaluating the pitting resistance of commercial alloys (316L and DSS 2205) and developing new duplex stainless steels with higher strength and pitting (thus, CISCC) resistance for potential canister application. The pitting resistance is measured using typical 3-electrode systems as pitting potential (Epit) and critical pitting temperature (CPT). The chemical compositions were set by considering a balance between microstructural phase fraction and pitting resistance equivalent number (PREN). Microstructural refinement with thermo-mechanical processing have been conducted, and the model alloys are currently evaluated for mechanical properties, pitting and CISCC resistance.

Releated Publication

More view

Releated Publication

More view

Zr-based alloys

Releated Publication More viewPressurized thermal shock of RPV

Releated Publication More viewAdvanced fabrication process

Evaluation of 3D printing for nuclear application

3D printing technology, which is in the spotlight as the next generation technology, is considered for manufacturing several parts of nuclear power plants where aren’t produced any more or are too expensive to import. Before the application of addictive manufacturing technology into nuclear field, the evaluation of mechanical properties and corrosion behavior in simulated PWR environments of addictive manufactured materials should be performed. Therefore, our group, first, evaluate the mechanical properties such as tensile, fatigue behavior by comparison with commercial alloys. And, second, we are trying to improve their mechanical properties as same or higher level than commercial alloys by understanding of the relationship between their microstructures and mechanical properties and by post-treatment such as HIP (hot isostatic process) and heat treatment. Consequently, our goal is to ensure that addictive manufacturing technology is used safely in the nuclear industry.

Advanced alloy development

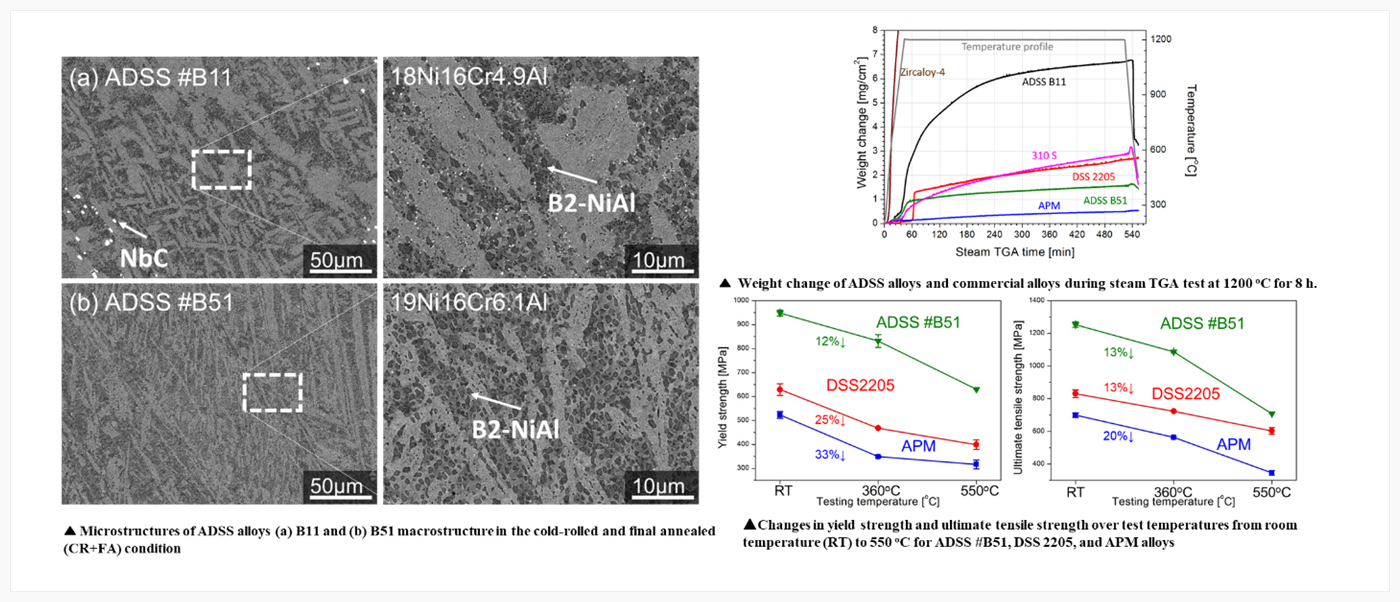

Alumina-forming Duplex Stainless Steels (ADSS) for ATF application

Since Fukushima accident in 2011 where dramatic high-temperature oxidation of Zr alloy cladding and excessive hydrogen production led to detrimental explosion, the replacement of the current Zr alloy cladding with so called accident tolerant fuel (ATF) claddings has been one of the hottest issues in worldwide nuclear community. Such ATF claddings should show superior oxidation resistance in high-temperature steam (up to 1200C) that excessive hydrogen production can be reduced under the anticipated beyond-design basis accident (BDBA) condition. One concept for ATF claddings is high-strength Fe-base alloys like FeCrAl alloys. The alloys have extremely high oxidation resistance at the high temperature by forming a protective alumina layer. However, economical fabrication of thin-tube and severe embrittlement during LWR operation period. In addition, the cladding tube should be thinner (~300 μm anticipated) to compensate the higher neutron-absorption cross-section, which requires higher strength than current Zr-based claddings. In this group, Alumina-forming Duplex Stainless Steels (ADSS) have been developed as ATF cladding materials to overcome those drawbacks. By adding Ni alloying element, we introduced austenite phase to compensate the brittle ferrite phase. In addition, the formation of NiAl phase make ADSS alloys stronger. In previous our works, ADSS showed good high-temperature oxidation resistance and PWR corrosion resistance also have extremely high strength and enough ductility to be drawn to thin tubes. Recently, with help of KEPCO Nuclear Fuel Co., more than a meter-long ADSS tubes with 0.3 mm thickness were successfully fabricated using conventional cold-pilgering process. Nonetheless, lots of additional evaluations including neutronic, thermal hydraulic, mechanical performances, and fabricability are needed for actual nuclear power plant applications. Also, further optimization of thermo-mechanical process and microstructure are underway. Currently, long-term thermal aging (+ irradiation), corrosion and SCC behaviour in various environments, and weldability are investigated.

Releated Publication

More view

Releated Publication

More view

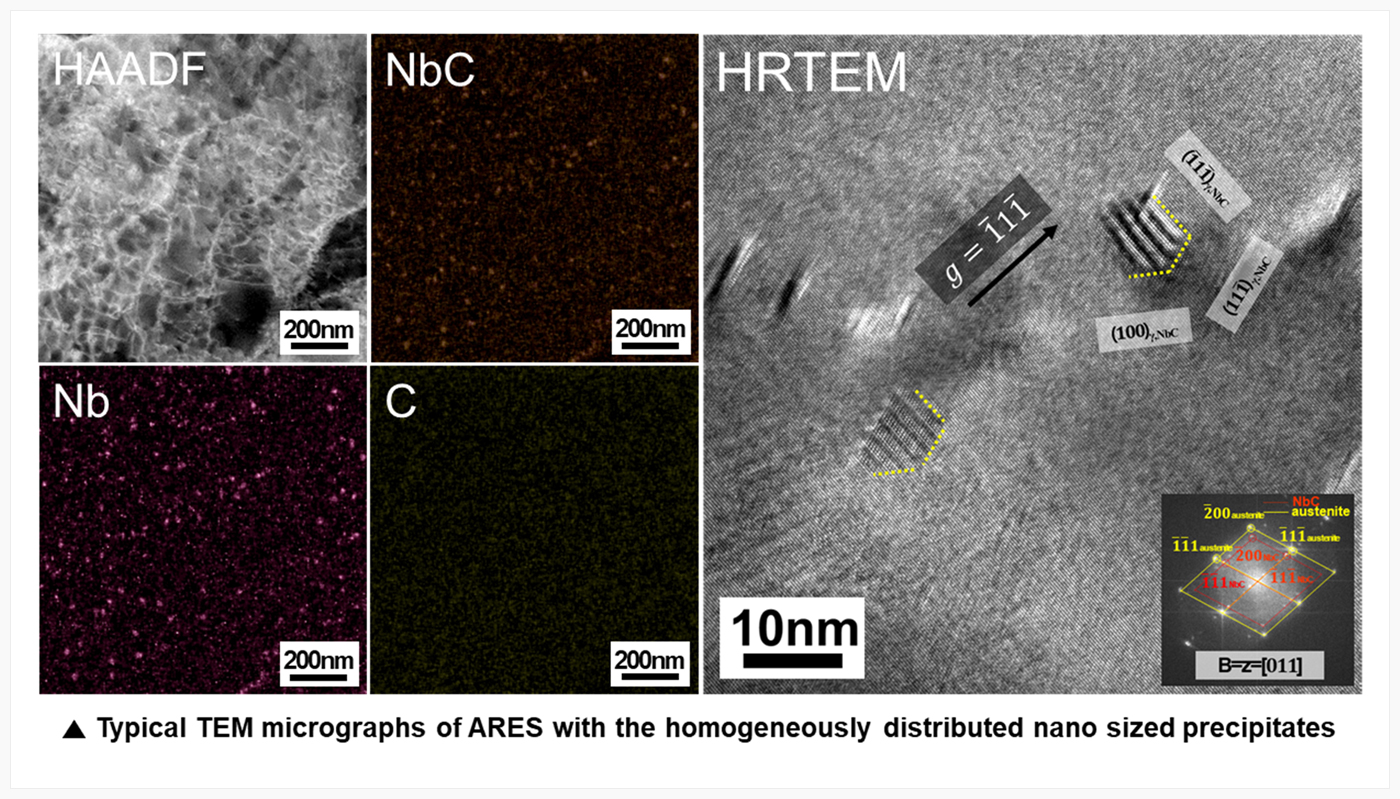

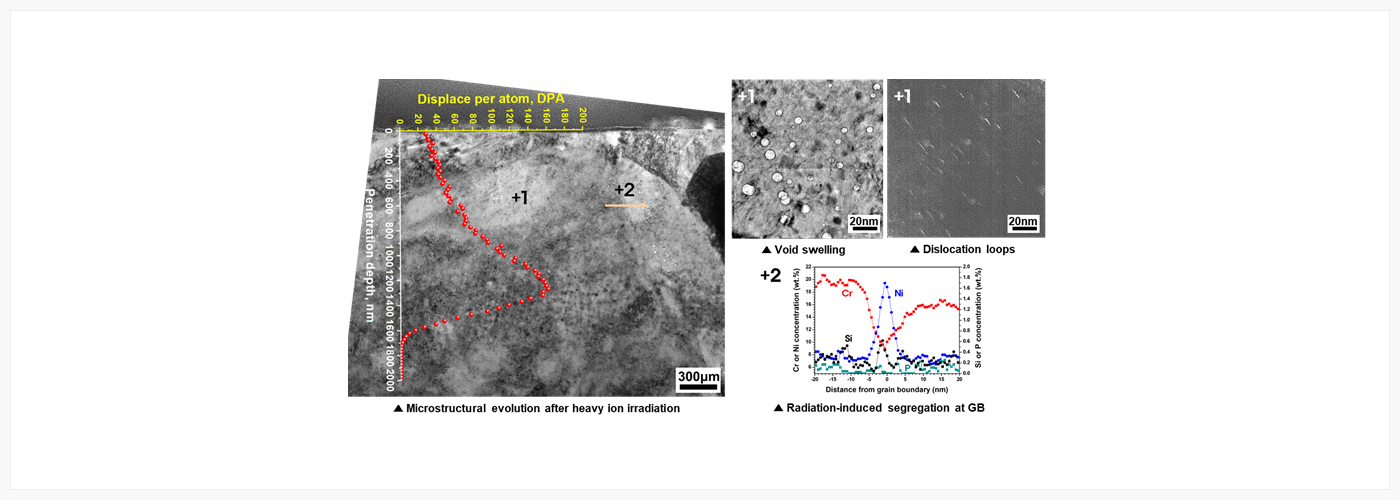

Development of nano carbide dispersed advanced radiation resistant austenitic stainless Steels

The long-term stability of structural materials in highly irradiating environments have been considered a critical issue for future generations of advanced reactors. Generally, neutron irradiation of austenitic stainless steels used in light water reactors causes radiation damage from displacement cascades. With relatively high-dose (>10dpa) neutron irradiation, formations of voids, dislocation loops, and precipitates are the major microstructural changes in austenitic stainless steels. Meanwhile, for the application of austenitic stainless steels as structural materials for fusion reactors, severely poor swelling resistance is also critical issue under the high fast neutron fluence. In addition, high temperature mechanical property, helium embrittlement, and magnetic property have been considered as issues to apply for fusion reactor internal materials of austenitic stainless steels. The effective approaches of improving the resistance to swelling and helium embrittlement are to introduce numerous sink sites for vacancies and helium atoms, such as grain boundaries and precipitates. Recently, this group developed a new approach based on conventional steelmaking processes and successfully formed high density of uniformly distributed nano sized carbides in austenite matrix. The composition of nano carbide dispersed advanced radiation resistant austenitic stainless steel (ARES) was further optimized to increase corrosion (IASCC) resistance for fission grade (ARES-L), and to reduce the long-term radioactivity for fusion grade (ARES-F). Though the calculation suggested the “sink strength” would be sufficient, the performance of the swelling resistance of the developed alloys has been evaluated by heavy ion irradiation.

Releated Publication

More view

Releated Publication

More view

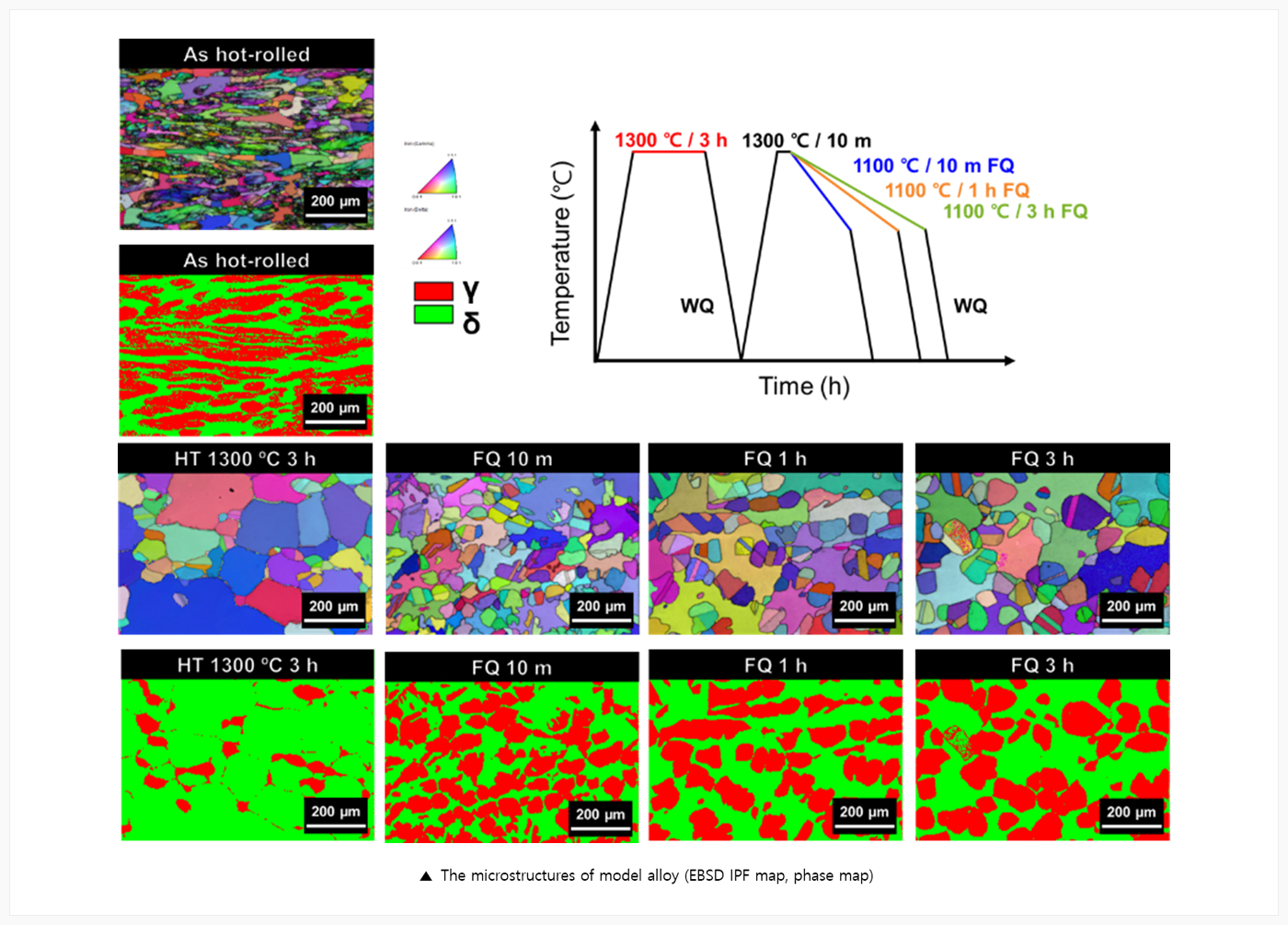

Development of high strength canister material with improved CISCC resistance

As the most of dry storage facilities are located near the nuclear power plant sites near the sea, the canister materials would be exposed to chloride-containing humid environment during the storage periods of tens of hundreds of years. As spent nuclear fuels are stored within the canisters, it is essential to maintain the structural integrity of canisters to avoid radioactive material leakage. Currently, 304 and 316 based austenitic stainless steels are used as canister materials, and several instances of chloride induced stress corrosion cracking (CISCC) have been reported abroad. The presence of residual stresses around the weld region in combination with the aggressive chloride environment, make it highly susceptible to pitting corrosion and consequent CISCC formation. In this group, we are developing duplex stainless steels with higher strength and improved CISCC resistance for potential canister application. The chemical compositions of Advanced Canister alloys with pitting Resistant and Strength (ACRS) were determined by considering a balance between microstructural phase fraction and pitting resistance equivalent number (PREN) as well as cost. Microstructural refinement with thermo-mechanical processing have been conducted, and the model alloys are currently evaluated for mechanical properties, pitting and CISCC resistance.

Thermal aging of stainless steels

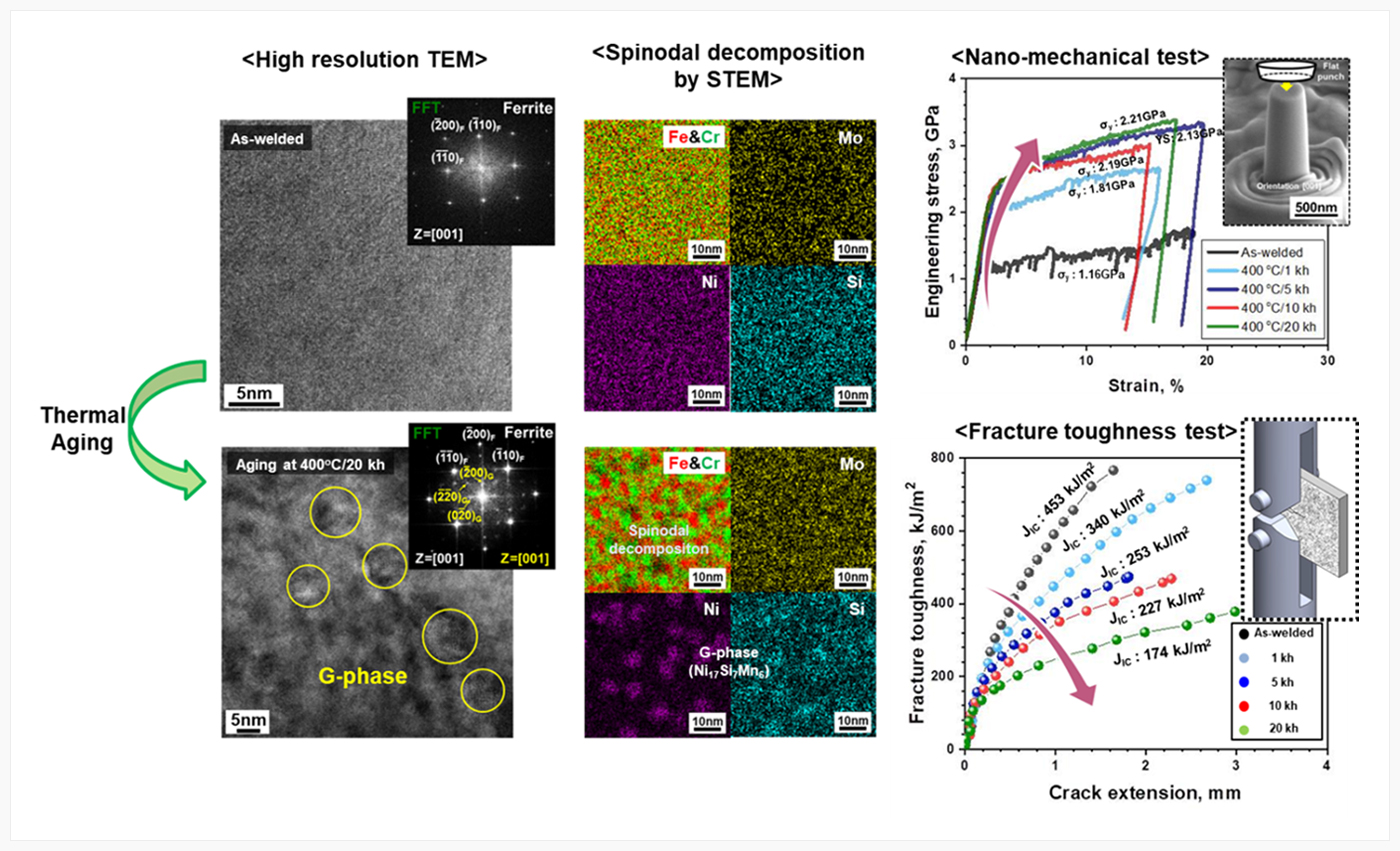

Thermal aging embrittlement of CASS and ASSW

Cast austenitic stainless steels (CASSs) and austenitic stainless steel welds (ASSWs) have been extensively used as primary coolant piping systems of light water reactors (LWRs). Especially, a certain amount of δ-ferrite is required in ASSWs to prevent hot cracking during the welding process. Though the presence of δ-ferrite provides high strength and stress corrosion cracking (SCC) resistance, CASSs and ASSWs are susceptible to thermal aging embrittlement after long-term service at temperature of 290 – 343oC in LWRs, resulting in embrittlement or loss fracture resistance. It has been well known that phase separation in δ-ferrite into Fe-rich (α) and Cr-rich (α’) phases induced by spinodal decomposition and formation of intermetallic G-phase are responsible for such degradation of mechanical properties. In order to emulate long term service in LWRs and evaluate residual life, several CASSs and ASSWs were thermally aged at 343~425 oC, where the phase separation of ferrite takes place by spinodal decomposition rather than nucleation and growth. Further, nanopillar compression test and fracture toughness test were performed to assess degradation of ferrite and bulk fracture property. It seems that though spinodal decomposition and thermal aging embrittlement are related, there are other factors to be considered to link the two phenomena, such as G-phase formation, precipitation on the phase boundaries, and interface effect. We are developing the comprehensive model based on test and FEM simulation (with help of other research group) to predict the thermal aging embrittlement of CASS and ASSWs. In addition, the corrosion behaviour of thermally-aged ASSWs in PWR primary are water is studied.

Releated Publication

More view

Releated Publication

More view

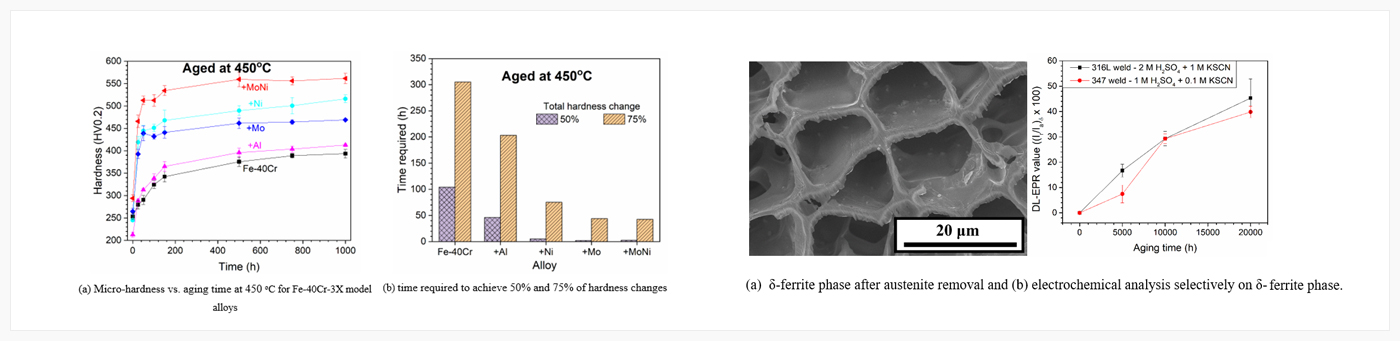

Assessment of thermal aging embrittlement of ferritic and duplex stainless steels

Commercial duplex stainless steels are usually limited in high temperature application due to the concern of the thermal aging embrittlement in ferrites. Recently, it has been reported that the addition of Al somewhat slow down the spinodal decomposition in FeCrAl alloys and ADSS developed in this group. We realized despite the extensive tests and studies, the exact mechanism and the role of alloying elements on spinodal decomposition and thermal aging embrittlement are still unclear. Thus, we are investigating the role of individual alloy element (or 3-rd element) in Fe-Cr model alloy on thermal aging embrittlement by mechanical testing and phase-field modelling simulation. We found some discrepancy between model prediction and test results, which could be used to improve modeling parameters. In addition, thermal aging behaviors of commercial alloys (APM, APMT, DSS 2205) and newly developed ATF alloys (ADSS and AFS) are studied. To characterize the changes in δ-ferrite phase, we selectively removed the parent austenite matrix and the residual δ-ferrite phase was left behind. Nanopillar compression tests were conducted selectively on the δ-ferrite phase to measure the change in mechanical properties while eliminating the interference from the austenite matrix. In addition, the corrosion resistance change in aged δ-ferrite were measured using electrochemical analysis after selective dissolution of austenite.

Releated Publication

More view

Releated Publication

More view

Radiation damage

Irradiation embrittlement and swelling of stainless steel welds

Many of the internal structure of LWRs are joined by welding, forming austenitic stainless steel welds (ASSWs). Typical ASSWs in the reactor internals contains ~10% of ferrite, which is subjected to thermal aging embrittlement and irradiation embrittlement during long-term operation. Thus, the combined effect of thermal aging and neutron irradiation could result in embrittlement kinetically faster than individual effect by either thermal aging or neutron irradiation. The as-welded and thermally aged weld specimens were irradiated up to 10 dpa by proton in MIBL (Michigan ion beam laboratory) to emulate effect of neutron irradiation in terms of hardening. For each constituent like austenite and ferrite, radiation defects induced by proton irradiation are being observed using TEM. Especially for ferrite phase, acceleration of phase separation into Fe-rich and Cr-rich phases and formation of other secondary phases by RED (radiation enhanced diffusion) will be characterized by APT (atom probe tomography) analysis. In addition, coupling with nano-mechanical properties by nanopillar compression tests, possible hardening mechanisms and explanations under thermal aging and irradiation environment will be proposed in the future.

Evaluation of radiation resistance for austenitic stainless steels

Austenitic stainless steels (SSs) are used extensively as structural alloys in the reactor internal components because of their relatively high strength, ductility, and fracture toughness. Meanwhile, exposure to neutron irradiation for extended periods not only changes the microstructure and microchemistry of these steels, but also degrades their mechanical properties. Other irradiation-related degradation issues are changes in material dimensions due to void swelling and stress relaxation due to radiation creep. Although several reviews have been written about irradiation effects on microstructure in stainless steels, the evolution of microstructure under irradiation conditions relevant to reactor cores is still not fully understood partially due to the lake of data. We are focusing on investigating the microstructure of commercial (304 and 316) and newly developed (ARES) austenitic stainless steels irradiated with proton or heavy ion under conditions relevant to reactor cores (~ 50 dpa) and fusion blanket (> 200 dpa). The long-term goal of our group is evaluating the mechanisms of microstructural evolution in austenitic stainless steel under irradiation conditions relevant to reactor core components by analyzing the ion irradiated microstructure and the available neutron-irradiated results.

High temperature oxidation for advanced power systems

In the competitive power generation market, development of advanced power generation system with higher efficiency requires higher operating temperatures. Therefore, the materials with high temperature capabilities such as corrosion resistance, strength, creep resistance, and microstructure stability are needed. In this group, the interested high temperature power systems are high-temperature or very-high temperature gas-cooled reactors (HTGR/VHTR), sodium-cooled fast reactors (SFR), advanced power systems using super-critical carbon-dioxide (S-CO2) systems including direct or indirect oxy-fuel combustion systems and concentrated solar power systems. For such high temperature applications, austenitic alloys are known to have better materials compatibility and structural integrity compared to ferritic-martensitic alloys (FMS). We are evaluating the corrosion (or, high temperature oxidation) behaviour of several austenitic alloys in wide ranges of high temperature environments. Also, the changes in mechanical properties due to such high temperature exposure are evaluated and the results are discussed in view of the oxidation behaviour. The information gained through the studies will be used to develop better and economical austenitic alloys for high temperature applications.

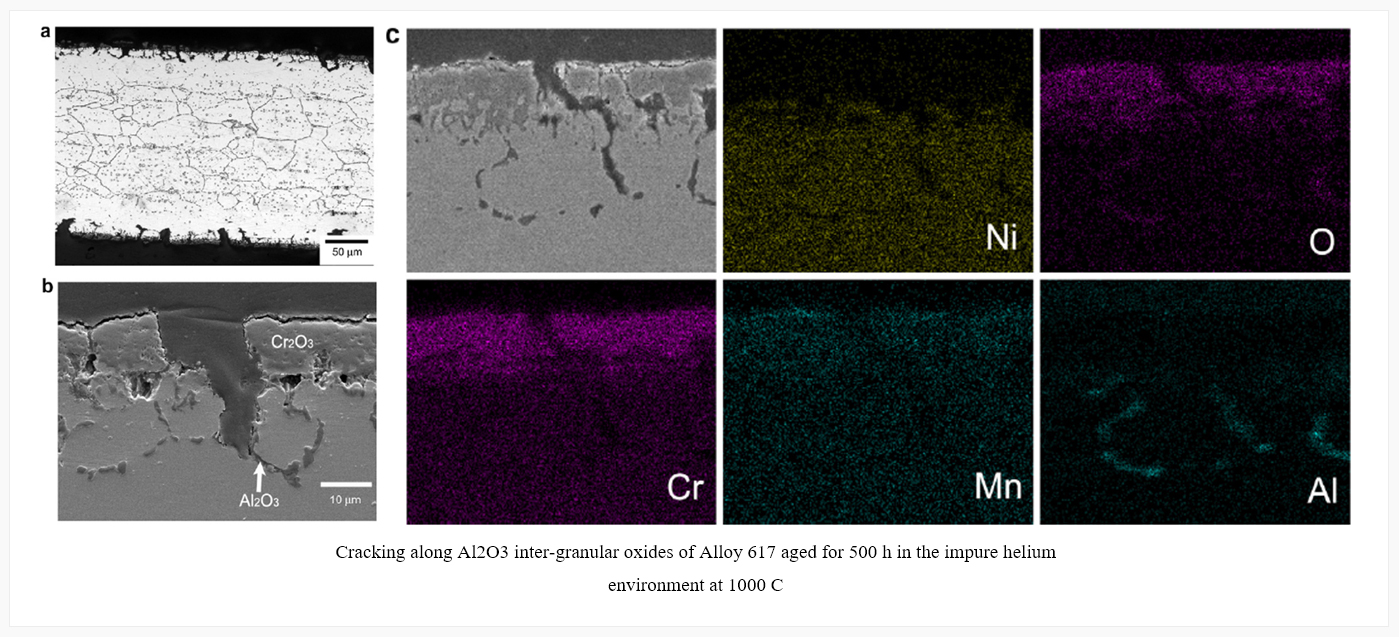

Corrosion behavior of structural materials for high temperature gas reactors

High-Temperature or very high-temperature gas-cooled reactors (HTGR/VHTR) is one of the generation IV reactor designs notable for its high operating temperatures of above 750 °C. This grants high thermal efficiencies, while also enabling industrial applications such as process heat and hydrogen generation. On the other hand, the high-temperature exposure presents a challenge for structural materials, as creep and corrosion become significant material degradation modes. Thus, proper selection of structural materials for key components such as the hot gas duct and intermediate heat exchanger (IHX) is necessary considering these aspects. Ni-base superalloys Alloy 617 and Alloy 230 have been considered as candidate materials for the key components in HTGR/VHTR. The two alloys are among the most creep resistant materials at high temperatures above 900 °C. In this group, the high temperature oxidation behaviour of these candidate alloys and resulting mechanical property changes has been experimentally investigated. The anticipated operating environments are helium, impure helium, steam and hydrogenated steam (for high temperature electrolysis to produce hydrogen). It was found that Alloy 230 showed somewhat better oxidation resistance than Alloy 617, but the mechanical property changes during long-term exposure was observed. Meanwhile, diffusion bonding resulted in decrease in tensile ductility for both alloys, especially at high temperature. Currently, model alloys are being developed to improve oxidation resistance and creep properties of those alloys.

Releated Publication

More view

Releated Publication

More view

Advanced alloy development

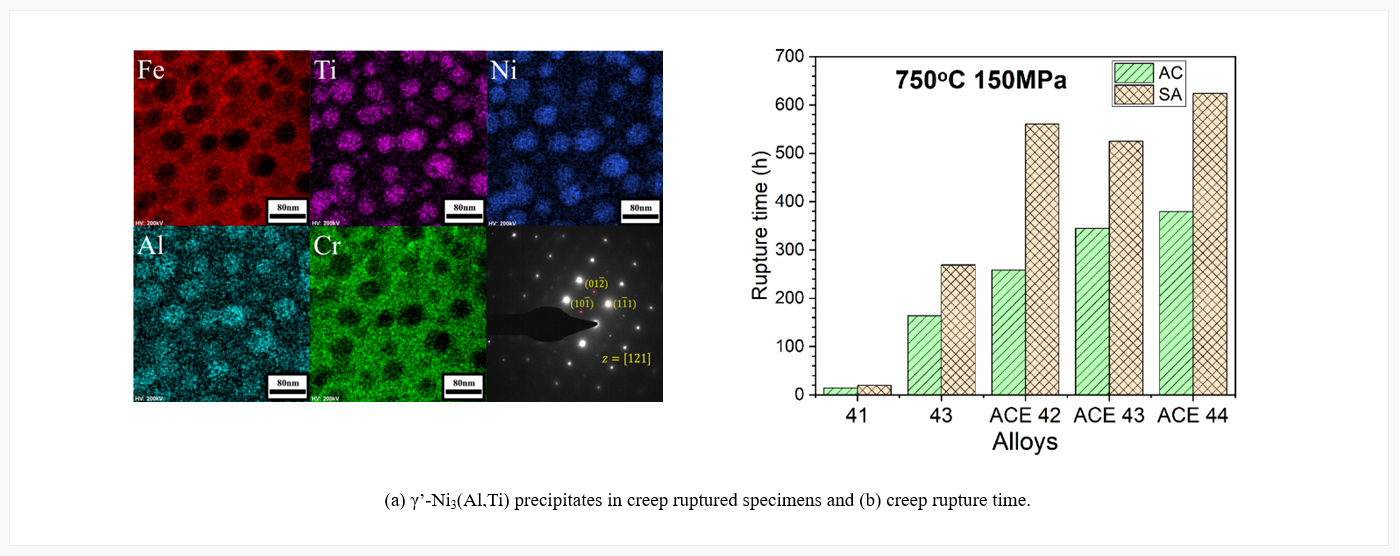

Development of austenitic stainless steels with enhanced creep-strength

The advanced power plants with increased thermal efficiency necessitates structural materials to withstand higher temperature and stress loads. The structural materials must possess excellent creep and oxidation resistance in the temperature range of 500 – 800 oC in aggressive oxidizing environments. Typically, Ni-based alloys with γ’-Ni3(Al) precipitates exhibiting superior creep-strength are used in these demanding requirements, but are not economical for competitive electricity market. For example, the economics of S-CO2 systems is considered dependent on the cost of high temperature components like heat exchangers. Recently, Fe-based austenitic stainless steels with γ’-Ni3(Al,Ti) precipitates were developed with improved creep-strength and oxidizing resistance, and can be considered for potential replacement of Ni-based alloys. In our research group, we are intended to further improve the creep-strength with increased stability and number density of γ’-Ni3(Al,Ti) and other strengthening precipitates. The compositions of Advanced Creep resistance Enhanced Stainless steels (ACES) were selected based on the thermodynamic phase stability calculations and the microstructure was optimized with proper thermo-mechanical treatments. The air creep tests for these alloys are conducted at 750 oC, while the oxidation resistance is being evaluated in high temperature steam and supercritical-carbon dioxide (S-CO2) environment.

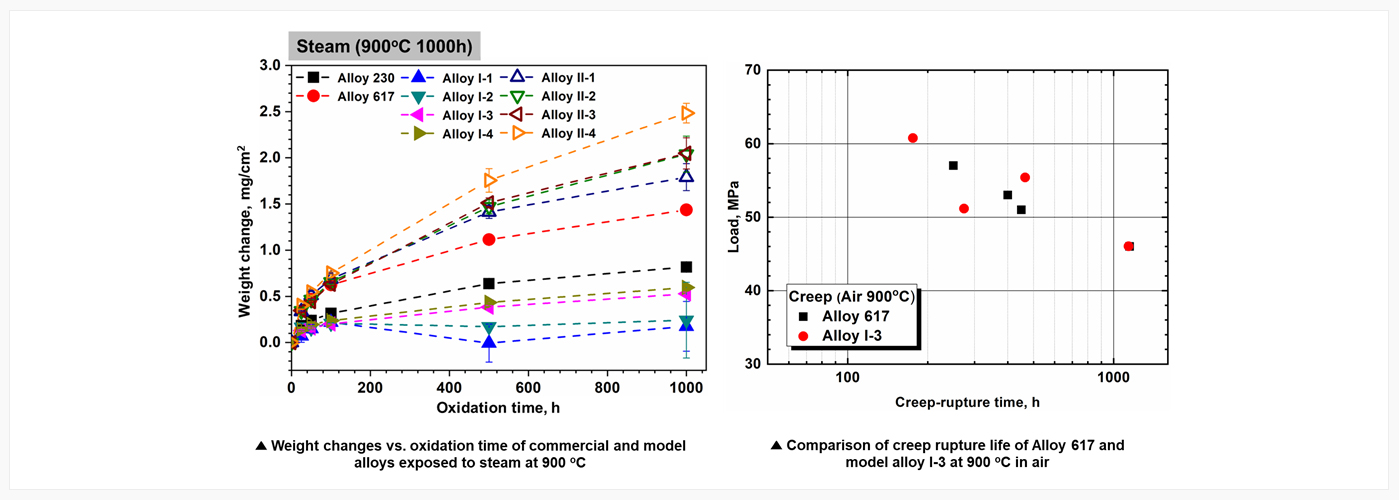

Development of modified alloy 617 for improved oxidation and creep resistance

Alloy 617 is the most widely studied alloy for the high temperature nuclear power plant application such as high temperature or very-high temperature gas-cooled reactors (HTGR/VHTR). Many studies showed that, despite Alloy 617 shows comparable creep rupture life than Alloy 230, Alloy 617 exhibited higher weight gains than Alloy 230 in various VHTR-related environments. Also, the internal oxidation caused by the small amount of Al was found to be associated the cracking from the surface. Therefore, development of modified Alloy 617 with adjustment of minor alloy elements is underway in this group. The model alloy exhibited improved high temperature oxidation resistance compared to the commercial Alloy 617. The preliminary creep test showed that one of the model alloys showed comparable creep properties. Additional creep tests are underway to confirm the creep properties and creep mechanisms. In addition, we found that the properties of diffusion-bonded joint were much improved for the model alloys, which provide the guidance for better PCHE fabrication.

Releated Publication

More view

Releated Publication

More view

High temperature oxidation for advanced power systems

In the competitive power generation market, development of advanced power generation system with higher efficiency requires higher operating temperatures. Therefore, the materials with high temperature capabilities such as corrosion resistance, strength, creep resistance, and microstructure stability are needed. In this group, the interested high temperature power systems are high-temperature or very-high temperature gas-cooled reactors (HTGR/VHTR), sodium-cooled fast reactors (SFR), advanced power systems using super-critical carbon-dioxide (S-CO2) systems including direct or indirect oxy-fuel combustion systems and concentrated solar power systems. For such high temperature applications, austenitic alloys are known to have better materials compatibility and structural integrity compared to ferritic-martensitic alloys (FMS). We are evaluating the corrosion (or, high temperature oxidation) behaviour of several austenitic alloys in wide ranges of high temperature environments. Also, the changes in mechanical properties due to such high temperature exposure are evaluated and the results are discussed in view of the oxidation behaviour. The information gained through the studies will be used to develop better and economical austenitic alloys for high temperature applications.

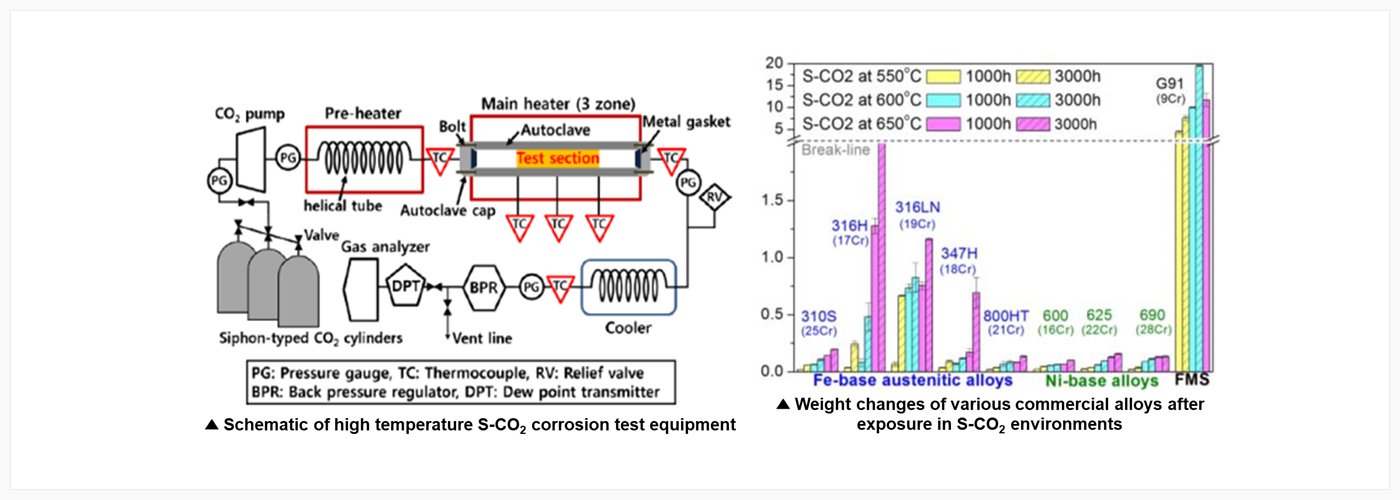

Compatibility of structural materials for high temperature supercritical-carbon dioxide systems

The supercritical-carbon dioxide (S-CO2) Brayton cycle is a crosscutting power conversion technology being developed for various energy applications such as next generation nuclear, fossil, and concentrated solar power plants. Compared to the conventional steam Rankine cycle and other cycles using coolants such as helium (He), the S-CO2 Brayton cycle is advantageous in terms of efficiency, system footprint, and simplicity of turbomachinery. In this group, compatibility of various austenitic alloys, especially in terms of corrosion behaviors in high temperature and pressure S-CO2 environment, have been studied. Generally, Ni-base alloys exhibited superior corrosion resistance compared to austenitic stainless steels thanks to the formation of a thin and adherent Cr-rich oxide layer. On the other hand, the corrosion behaviors of Fe-base alloys in S-CO2 were found to be dependent on Cr content, grain size, and exposure temperature. To improve the corrosion resistance of Fe-base alloys, surface modification techniques are applied. In addition, effects of various impurities such as H2O and O2 on corrosion behaviors of materials in high temperature S-CO2 environments are under evaluation. Also, changes in tensile properties after prolonged S-CO2 exposure are investigated. Recently, creep properties in S-CO2 environment are evaluated for the first time, which showed much reduced creep rupture life for austenitic alloys.

Releated Publication

More view

Releated Publication

More view

Surface modification for improvement of corrosion behaviors in high temperature environments

Generally, Ni-base alloys are known to exhibit better corrosion resistances in high temperature oxidizing environments compared to Fe-base alloys, owing to the formation of a continuous and adherent Cr-rich oxide layer. In addition, good high temperature creep properties make Ni-base alloys appropriate candidate materials for next generation power plants operating above 700 oC. Nonetheless, for applications in aggressive environments for prolonged period, the oxidation resistance needs to be further improved. Also, use of Ni-base alloys would accompany significant increases in cost compared to Fe-based alloys. Meanwhile, while Ni-base alloys may be necessary for crucial components such as turbine blades, it may be more practical to use Fe-base alloys for most other components that are not exposed to such high temperatures or stresses. From this viewpoint, corrosion resistance improvement of such alloys by surface-modification is of practical significance. This process is also beneficial in that corrosion resistance while bulk chemical composition and mechanical properties are retained. Thus, in this group, the surface enrichment of various alloys with elements such as Cr, Al, Si using physical vapor deposition or electroplating followed by electron-beam re-melting or interdiffusion heat treatment (IDHT) have been conducted and of their corrosion behaviors in high temperature environments are evaluated to assess the effectiveness of such methods.

Releated Publication

More view

Releated Publication

More view

Advanced fabrication process

Diffusion bonding for microchannel heat exchangers

Diffusion welding or bonding is one of the joining methods grouped under solid-state welding processes. It is characterized by producing joints by maintaining contact of joining work pieces by applying pressure at high temperature under the melting point of the base materials in a controlled environment for a specified duration. If ideally performed, diffusion bonded joints show similar mechanical properties as the base material. In addition, diffusion bonding enables joining of multiple plates for fabrication of microchannel heat exchangers such as printed channel heat exchanger (PCHE), which is difficult using other joining methods such as fusion welding or brazing. The quality of a diffusion bond is sensitive to various bonding parameters such as temperature, pressure and duration. In addition, selecting optimum diffusion bonding conditions would differ for varying alloys and involve consideration of each alloys’ mechanical properties, microstructures, and chemical compositions. Meanwhile, according to American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, only 304L, 316L, 2205 duplex stainless steels are allowed for fabrication of microchannel heat exchangers. However, these materials are not appropriate for use in high temperature environments above 650 oC. Thus, efforts are underway to codify diffusion bonding of Alloy 800H on ASME.

Releated Publication

More view

Releated Publication

More view

Fusion materials

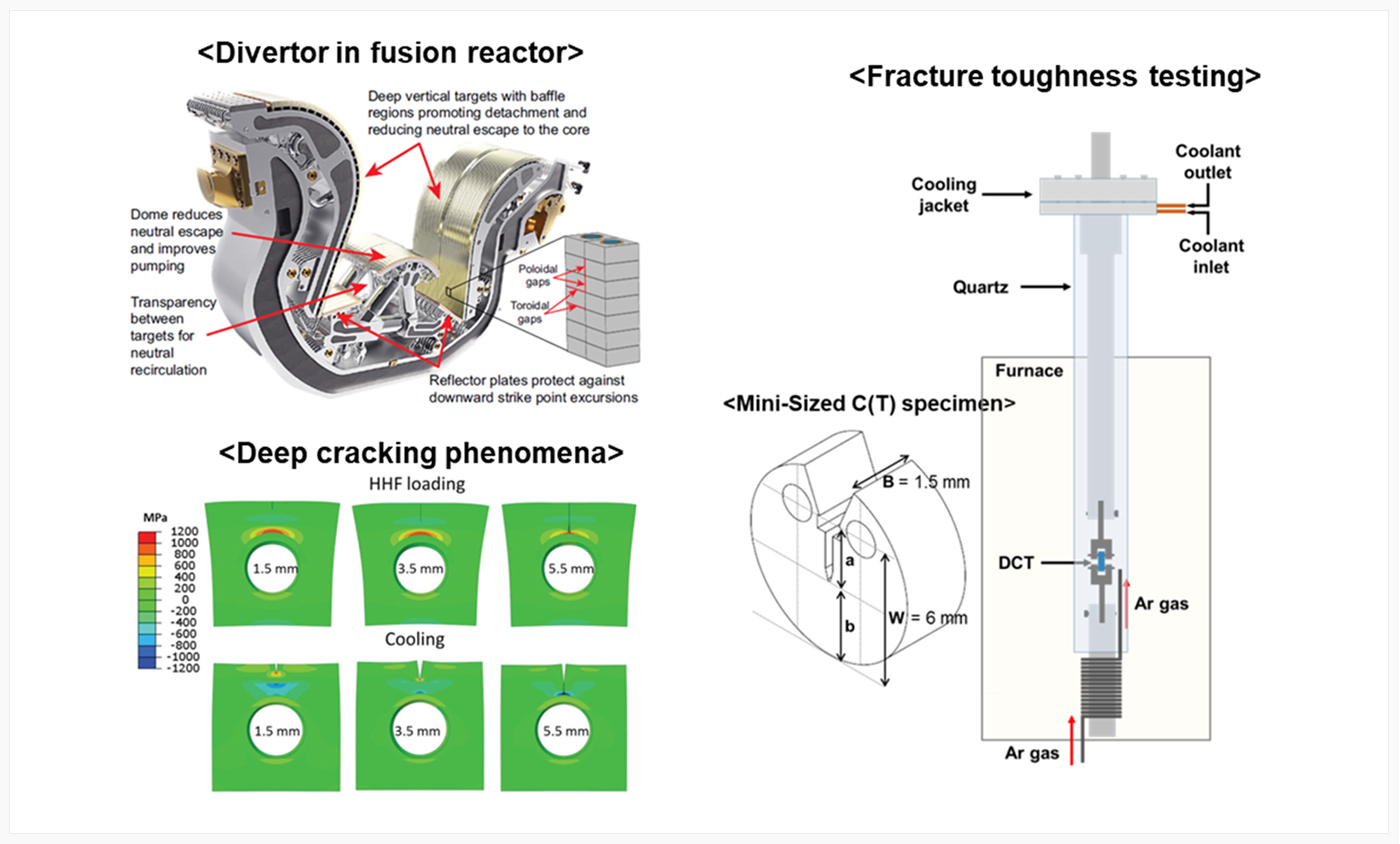

Evaluation of fracture toughness of tungsten as a divertor application

Pure tungsten (W) is considered for plasma-facing materials of the fusion reactors including diverter components. For fusion applications, tungsten has various advantages such as high melting point, high thermal conductivity, low tritium retention, and high erosion resistance for application as diverter materials. Meanwhile, it has relatively high ductile to brittle transition temperature (DBTT), poor oxidation resistance at high temperature, low recrystallization temperature, and inherent brittleness. The inherent low fracture toughness of tungsten and resulting poor fracture resistance could be limiting factors in structural materials application. In addition, under high heat-flux (HHF) loading condition, temperature of surface of tungsten armor is close to the recrystallization temperature. Also, due to repetitive HHF loading, fatigue crack could be initiated on the surface and followed by crack propagation under tensile loading condition, which is so called deep cracking phenomena. Therefore, evaluation of fracture toughness and fatigue behaviour of W is essential to structural integrity analysis of W diverters. Nonetheless, published fracture toughness data and related studies are rare in current literature due to difficulties fatigue pre-cracking and fratire toughness test. Recently, we developed the reliable fatigue pre-cracking method to introduce sharp pre-crack. Using that methods, we successfully tested fracture toughness test using mini-sized disc-type compact tension (DCT) specimen from room temperature to 700 oC. Small-punch tests are also performed to be compared with DCT test results. Currently, the effect of loading rate and recrystallization on the fracture behaviour of ITER-grade W is investigated.

Releated Publication

More view

Releated Publication

More view

Development of swelling resistant low activation austenitic stainless steel for fusion application

As described in 4.2 and 6.2, irradiation resistance of austenitic stainless steels can be improved by formation of nano-sized precipitate in the austenite matrix. Poor swelling resistance of austenitic stainless is one of the main reasons why they are excluded in high temperature, high neutron dose application like fuel cladding of SFR and fusion blanket, despite other excellent resistance to irradiation embrittlement, corrosion, hydrogen embrittlement, and so on. Especially, non-magnetic property would be beneficial in magnetic confinement fusion reactors like ITER. Therefore, based on ARES-L, fusion-grade radiation resistant ARES (ARES-F) is being developed. To meet the low activation criteria for waste disposal, alloying elements were fine tuned to determine several candidate alloys of ARES-F. Currently, the composition and thermo-mechanical process are being optimized. For the selected ARES-F alloys, swelling resistance will be measured using heavy ion irradiation experiments.

Development of W coating on graphite for ITER-Like Wall

Many of the operating fusion devices including KSTAR are using carbon-based first wall because of the good plasma-compatibility. However, for the development of fusion power plant, the high erosion rate of carbon-based first wall may be a serious problem. Therefore, more erosion resistant W was chosen as the first wall, or plasma facing materials (PFM), of the ITER and DEMO fusion reactors. With ITER still under construction, the ITER-Like Wall (ILW) was developed by coating thick layer of W on existing first wall of operating fusion devices. As a part of such effort, we developed thin coating layers of W or W/Mo on graphite using physical vapor deposition (PVD) method. The performance of such coating layers was evaluated under D+ ion irradiation.

Releated Publication

More view

Releated Publication

More view

-

1

Junjie Chen, Changheui Jang*, Byeong Seo Kong, Qian Xiao, Gokul Obulan Subramanian, Ho-Sub Kim, Ji Ho Shin, “Effect of thermal aging on the corrosion behaviour of austenitic stainless steel welds in the simulated PWR primary water,” Corrosion Science, Vol. 172, 108730, Aug. 2020.

LINK -

2

Oh Hyun Kwon, Ji Ho Shin, Changheui Jang*, Jong-Sung Yoo, Ho-Sub Kim, Young-il Kwon, Hyun Gil Kim, “Effect of Nb on the electrical resistivity of ZrO2 layer formed on Zr alloys,” J. of Nuclear Materials, Vol. 536, 152202, Aug. 2020.

LINK -

3

Ho-Sub Kim, Jiho Shin, Byeong Seo Kong, Sunghoon Hong, Seungjin Oh, Jong-Dae Hong, Changheui Jang*, Sanghoon Lee, “Effects of heat treatment on mechanical properties and sensitization behavior of materials in dissimilar metal weld,” IJPVP, Vol.172, pp.17-27, May 2019.

LINK -

4

Junjie Chen, Zhanpeng Lu*, Fanjiang Meng, Xuelian Xu, Qian Xiao, Ho-sub Kim, Changheui Jang*, “The oxidation behaviours of Alloy 690 tube in simulated PWR secondary water with the effect of solid diffusion hydrogen,” J. of Nuclear Materials, Vol. 519, pp.179-191, April 2019.

LINK -

5

Gokul Obulan Subramanian, Byeong Seo Kong, Sunghoon Hong, Ho Jung Lee, Changheui Jang*, “Electrochemical behavior of δ-ferrite in the thermally aged austenitic stainless steel welds,” Scientific Report, 8: 15091, Oct. 2018.

LINK -

6

Jian Xu*, Tetsuo Shoji, Changheui Jang, “The effects of dissolved hydrogen on the corrosion behavior of Alloy 182 in simulated primary water,” Corrosion Science, Vol.97, pp.115–125, Aug. 2015.

LINK

-

1

Ho-sub Kim, Hyeon Bae Lee, Junjie Chen, Changheui Jang*, Tae Soon Kim, Gary L. Stevens, and Kawaljit Ahluwalia, “Effect of zinc on the environmentally-assisted fatigue behavior of 316 stainless steels in simulated PWR primary environment,” Corrosion Scienc, Vol.151, pp.97-107, May 2019.

LINK -

2

Junjie Chen, Andrieanto Nurrochman, Jong-Dae Hong, Tae Soon Kim, Changheui Jang*, Yongsun Yi, “Comparison of oxide layers formed on the low-cycle fatigue crack surfaces of Alloy 690 and 316 SS in a simulated PWR environment,” NET, Vol.51, no.2, pp.479-491, April 2019.

LINK -

3

Junho Lee, Myeong-Gyu Seo, Jong-Dae Hong, Tae Soon Kim, Changheui Jang*, “Low Cycle Fatigue Behavior of Hot-bent 347 Stainless Steels in Simulated PWR Water,” J. of Mech. Sci. Tech., Vol. 30, no.11, pp.4931-4936, Nov. 2016.

LINK -

4

Jong-Dae Hong, Changheui Jang*, Tae Soon Kim, “Effects of mixed strain rates on low cycle fatigue behaviors of austenitic stainless steels in a simulated PWR environment,” Int. J. of Fatigue, Vol. 82, pp.292-299, Jan. 2016.

LINK -

5

J.D. Hong, J. Lee, C. Jang, “Low Cycle Fatigue Behaviors of Alloy 690 in a Simulated PWR Water - Effects of Dynamic Strain Aging and Hydrogen,” Materials Science and Engineering – A, Vol 611, pp.37-44, August 2014.

LINK -

6

Changheui Jang*, Hun Jang, Jong-Dae Hong, Pyung-Yeon Cho, Hyunchul Cho, Tae Soon Kim, Jae-Gon Lee, “Environmental Fatigue of Metallic Materials in Nuclear Power Plants – A Review of Korean Test Programs,” Nuclear Engineering and Technology, Vol. 45, no. 7, pp.929-940, Dec. 2013.

LINK -

7

Hun Jang, Jeong Hyeon Kim, Changheui Jang, Jae-Gon Lee, Tae Soon Kim, “Low-cycle fatigue behaviors of two heats of SA508 Gr.1a low alloy steel in 310 oC air and deoxygenated water – Effects of dynamic strain aging and microstructures,” Materials Science and Engineering – A, vol. 580, pp.41-50, September 2013.

LINK -

8

Hun Jang, Hyunchul Cho, Changheui Jang*, Tae Soon Kim, Chan Kook Moon, “Effect of Cyclic Strain Rate and Sulfides on Environmentally Assisted Cracking Behaviors of SA508 Gr. 1a Low Alloy Steel in Deoxygenated Water at 310 oC,” Nuclear Engineering and Technology, Vol. 40, no. 3, pp.225-232, April 2008.

LINK -

9

Hyunchul Cho, Byoung Koo Kim, In Sup Kim, Changheui Jang*, “Low cycle fatigue behaviors of type 316LN austenitic stainless steel in 310oC deaerated water - fatigue life and dislocation structure development,” Materials Science and Engineering - A, Vol. 476, pp.248-256, March 2008.

LINK -

10

Hyunchul Cho, Byoung Koo Kim, In Sup Kim, Changheui Jang*, Dae Yul Jung, “Fatigue Life and Crack Growth Mechanisms of the Type 316LN Austenitic Stainless Steel in 310oC Deoxygenated Water,” Journal of Nuclear Science and Technology, Vol. 44, no. 7, pp.1007-1014, 2007.

LINK

-

1

Abdullah Sinjlawi, Junjie Chen, Ho-Sub Kim, Hyeon Bae Lee, Changheui Jang*, Sanghoon Lee, “Role of residual ferrites on crevice SCC of austenitic stainless steels in PWR water with high-dissolved oxygen,” Accepted to Nuclear Engineering and Technology, April 2020.

LINK -

2

Eunsub Yun, Hansub Chung, Changheui Jang*, “Evaluation of Primary Water Stress Corrosion Cracking Resistance of Three Heats of Alloy 600 in 400oC Hydrogenated Steam Condition,” Metals, 2018, 8, 130, Feb. 2018.

LINK -

3

Yun Soo Lim*, Sung Woo Kim, Seong Sik Hwang, Hong Pyo Kim, Changheui Jang, “Intergranular Oxidation of Ni-Based Alloy 600 in a Simulated PWR Primary Water Environment,” Corrosion Science, Vol. 108, pp.125-133, July 2016.

LINK -

4

Rashid Al Hammadi, Yongsun Yi*, Wael Zaki, Pyungyeon Cho, Changheui Jang, “Mechanical factors in Primary Water Stress Corrosion Cracking of cold-worked stainless steel,” Nuclear Engineering and Desig, Vol. 301, pp.24-31, May 2016.

LINK -

5

Jong-Dae Hong, Changheui Jang*, and Tae Soon Kim, “PFM application for the PWSCC integrity of Ni-base alloy welds – development and application of PINEP-PWSCC,” Nucl. Eng. Tech, Vol.44 No.8, pp.961-970, Dec. 2012.

LINK

-

1

Qian Xiao, Changheui Jang*, Chaewon Kim, Hyunmyung Kim, Junjie Chen, Hyeon Bae Lee, “Corrosion behavior of stainless steels in simulated PWR primary water: the effect of composition and matrix phases,” Submitted to Corrosion Science, June 2020.

-

2

Chaewon Kim, Hyunmyung Kim, Changheui Jang*, Kangsan Kim, Yonghee Kim, Seungjae Lee, Hun Jang, “Feasibility assessment of the alumina-forming duplex stainless steels as accident tolerant fuel cladding materials for light water reactors,” accepted, Int. J. of Energy Research, Nov. 2019.

LINK -

3

Hyunmyung Kim, Hun Jang, Gokul Obulan Subramanian, Chaewon Kim, Changheui Jang*, “Development of alumina-forming duplex stainless steels as accident-tolerant fuel cladding materials for light water reactors,” J. of Nuclear Materials, Vol.507, pp.1-14, Aug. 2018.

LINK

-

1

Sara Al Saadi, Yongsun Yi*, Pyungyeon Cho, Changheui Jang, Philip Beeley, “Passivity breakdown of 316L stainless steel during potentiodynamic polarization in NaCl solution,” Corrosion Science, Vol.111, pp.720-727, Oct. 2016.

LINK -

2

M. Al Ameri, Y. Yi*, P. Cho, S. Al Saadia, C. Jang, P. Beeley, “Critical conditions for pit initiation and growth of austenitic stainless steels,” Corrosion Science, Vol.92, pp.209-216, March 2015.

LINK -

3

Y. Yi*, P. Cho, A. Al Zaabi, Y. Addad, C. Jang, “Potentiodynamic behaviour of AISI type 316 stainless steel in NaCl solution,” Corrosion Science, Vol. 74, pp.92-97, Sept. 2013.

LINK

-

1

Oh Hyun Kwon, Ji Ho Shin, Changheui Jang*, Jong-Sung Yoo, Ho-Sub Kim, Young-il Kwon, Hyun Gil Kim, “Effect of Nb on the electrical resistivity of ZrO2 layer formed on Zr alloys,” J. of Nuclear Materials, Vol. 536, 152202, Aug. 2020.

LINK -

2

Oh Hyun Kwon, Changheui Jang*, Junho Lee, Hu Young Jeong, Young-il Kwon, Jong Hoon Joo, Hongjin Kim, “Investigation of the Electrical Conductivity of Sintered Monoclinic Zirconia (ZrO2),” Ceramics International, Vol.43, pp.8236-8245, Aug. 2017.

LINK -

3

Sung Han Lee, Dong Su Kim, Sim Won Lee, Young Gyu No, Man Gyun Na*, Jae Yong Lee, Dong Hoon Kim, and Changheui Jang, “Diametral Creep Prediction of the Pressure Tubes in CANDU Reactors Using a Bundle Position-wise Linear Model,” Nucl. Eng. Tech., Vol. 43, No. 3, pp. 301-308, June 2011.

LINK -

4

Seungjin Oh, Changheui Jang*, Jun Hwan Kim, Yong Hwan Jeong, “Microstructure and hydride embrittlement of zirconium model alloys containing niobium and tin,” Materials Science and Engineering - A, Vol. 528, pp.3771-3776, Mar. 2011.

LINK -

5

Seungjin Oh, Changheui Jang*, Jun Hwan Kim, Yong Hwan Jeong, “Effect of Nb on hydride embrittlement of Zr-xNb alloys,” Materials Science and Engineering - A, Vol. 527, pp.1306-1313, March 2010.

LINK

-

1

Myung Jo JHUNG*, Young Hwan CHOI and Changheui JANG, “Structural Integrity of Reactor Pressure Vessel for Small Break Loss of Coolant Accident,” Journal of Nuclear Science and Technology, Vol. 46, No. 3, pp.310-315, 2009.

LINK -

2

Myung Jo Jhung*, Seok Hun Kim, Young Hwan Choi, Sunggyu Jung, Jong Min Kim, Ji Ho Kim, Jong Wook Kim, Changheui Jang, Yoon Suk Chang, Ki Sig Kang, “Structural Integrity Assessment of Reactor Pressure Vessels during Pressurized Thermal Shock,” J. of Mech. Sci. Tech., Vol.22, pp.1451-1459, August 2008.

LINK -

3

Changheui Jang*, Jounghoon Lee, Jong Sung Kim, and Tae Eun Jin, “Mechanical Property Variation within Inconel 82/182 Dissimilar Metal Weld between Low Alloy Steel and 316 Stainless Steel,” Int. J. of PVP, Vol 85/9, pp. 635-646, September 2008.

LINK -

4

Changheui Jang*, “Treatment of the Thermal–Hydraulic Uncertainties in the Pressurized Thermal Shock Analysis,” Nuclear Engineering and Design, Vol. 237, pp.143-152, Jan. 2007.

LINK -

5

Changheui Jang*, “Approximation Method for the Calculation of Stress Intensity Factors for the Semi-elliptical Surface Flaws on Thin-Walled Cylinder,” J. of Mech. Sci. Tech., Vol. 20, no. 3, pp.319-328, March 2006.

LINK -

6

M. J. Jhung*, Changheui Jang, et. al., “Round Robin Analysis for Probabilistic Structural Integrity of Reactor Pressure Vessel under Pressurized Thermal Shock,” J. of Mech. Sci. Tech., Vol 19, no. 2, pp.634-648, 2005.

LINK -

7

C.H. Jang*, S. C. Kang, H. R. Moonn, I.S. Jeong, T. R. Kim, “The Effects of the Stainless Steel Cladding in Pressurized Thermal Shock Evaluation,” Nuclear Engineering and Design, Vol. 226, pp.127-140, Dec. 2003.

LINK -

8

S.Y. Hong, C.H. Jang*, I.S. Jeong, “Experience of the integrity assessment of the highly embrittled reactor pressure vessel,” Nuclear Engineering and Design, Vol. 214, no. 1-2, pp.163-172, May 2002.

LINK -

9

I.S. Jeong*, C.H. Jang, J. H. Park, S.Y. Hong, T.E. Jin, H.G. Yeum, “Lessons Learned from the Plant-Specific PTS Integrity Analysis on an Embrittled Reactor Pressure Vessel,” Int. J. of PVP, Vol. 78, pp.99-109, Feb. 2001.

LINK -

10

C.H. Jang*, I.S. Jeong, S.Y. Hong, “The Effect of Flaw Orientation on the Integrity of PWR Pressure Vessel at the Events of Pressurized Thermal Shock,” Nuclear Engineering and Design, Vol. 197, no. 3, pp.249-264, May 2000.

LINK -

11

Myung Jo Jhung*, Youn Won Park, Changheui Jang, “Pressurized thermal shock analyses of a reactor pressure vessel using critical crack depth diagrams,” Int. J. of PVP, Vol. 76, pp.813-823, Oct. 1999.

LINK

-

1

Qian Xiao, Changheui Jang*, Chaewon Kim, Hyunmyung Kim, Junjie Chen, Hyeon Bae Lee, “Corrosion behavior of stainless steels in simulated PWR primary water: the effect of composition and matrix phases,” Submitted to Corrosion Science, June 2020.

-

2

Chaewon Kim, Hyunmyung Kim, Changheui Jang*, Kangsan Kim, Yonghee Kim, Seungjae Lee, Hun Jang, “Feasibility assessment of the alumina-forming duplex stainless steels as accident tolerant fuel cladding materials for light water reactors,” accepted, Int. J. of Energy Research, Nov. 2019.

LINK -

3

Hyunmyung Kim, Gokul Obulan Subramanian, Chaewon Kim, Hun Jang, Changheui Jang*, “400 °C aging embrittlement of FeCrAl alloys: Microstructure and fracture behavior,” Materials Science and Engineering – A, Vol. 743, pp.159-167, Jan. 2019.

LINK -

4

Hyunmyung Kim, Hun Jang, Gokul Obulan Subramanian, Chaewon Kim, Changheui Jang*, “Development of alumina-forming duplex stainless steels as accident-tolerant fuel cladding materials for light water reactors,” J. of Nuclear Materials, Vol.507, pp.1-14, Aug. 2018.

LINK

-

1

Ji Ho Shin, Ho-Sub Kim, Byeong Seo Kong, Gokul Obulan Subramanian, Sunghoon Hong, Ho Jung Lee, Changheui Jang*, “Development of thermo-mechanical process to form high density of uniformly distributed nanosized carbides in austenitic stainless steels,” Materials Science and Engineering – A, Vol.775. 138986, Feb. 2020.

LINK

-

1

Byeong Seo Kong, Jiho Shin, Gokul Obulan Subramanian, Junjie Chen, Changheui Jang*, Ye-eun Na, Dongchan Jang, Ho Jung Lee, Jun-Seog Yang, “Evaluation of thermal ageing activation energy of δ-ferrite in an austenitic stainless steel weld using nanopillar compression test,” Scripta Materialia, Vol.186, pp.236-241, Sept. 2020.

LINK -

2

Junjie Chen, Changheui Jang*, Byeong Seo Kong, Qian Xiao, Gokul Obulan Subramanian, Ho-Sub Kim, Ji Ho Shin, “Effect of thermal aging on the corrosion behaviour of austenitic stainless steel welds in the simulated PWR primary water,” Corrosion Science, Vol. 172, 108730, Aug. 2020.

LINK -

3

Jongbeom Kim, Sung-Sik Kang*, Jin-Gyum Kim, Byeong Seo Kong, Kyung-Mo Kim, Changheui Jang, Kyung Young Jhang, “Applicability of Nonlinear Ultrasonic Technique to Evaluation of Thermally Aged CF8M Cast Stainless Steel,” NET, Vol.52, pp.621-625, Mar. 2020.

LINK -

4

Hyunmyung Kim, Gokul Obulan Subramanian, Chaewon Kim, Hun Jang, Changheui Jang*, “400 °C aging embrittlement of FeCrAl alloys: Microstructure and fracture behavior,” Materials Science and Engineering – A, Vol. 743, pp.159-167, Jan. 2019.

LINK -

5

Gokul Obulan Subramanian, Byeong Seo Kong, Sunghoon Hong, Ho Jung Lee, Changheui Jang*, “Electrochemical behavior of δ-ferrite in the thermally aged austenitic stainless steel welds,” Scientific Report, 8: 15091, Oct. 2018.

LINK -

6

Ho Jung Lee, Byeong Seo Kong, Gokul Obulan Subramanian, Jaewon Hur, Changheui Jang*, Kyoung-Soo Lee, “Evaluation of thermal aging of δ-ferrite in austenitic stainless steel weld using nanopillar compression test,” Scripta Materialia, Vol. 155, pp.32-36, Oct. 2018.

LINK -

7

Changheui Jang*, Hun Jang, Sunghoon Hong, Jae Gon Lee, “Evaluation of the recovery of thermal aging embrittlement of CF8M cast stainless steels after reversion heat treatments,” IJPVP, Vol. 131, pp.67-74, July 2015.

LINK -

8

Hun Jang, Sunghoon Hong, Changheui Jang*, Jae Gon Lee, “The effects of reversion heat treatment on the recovery of thermal aging embrittlement of CF8M cast austenitic stainless steels,” Materials and Design, Vol. 56, pp. 517-521, April 2014.

LINK

-

1

Hyunmyung Kim, Gokul Obulan Subramanian, Chaewon Kim, Hun Jang, Changheui Jang*, “400 °C aging embrittlement of FeCrAl alloys: Microstructure and fracture behavior,” Materials Science and Engineering – A, Vol. 743, pp.159-167, Jan. 2019.

LINK -

2

Gokul Obulan Subramanian, Byeong Seo Kong, Sunghoon Hong, Ho Jung Lee, Changheui Jang*, “Electrochemical behavior of δ-ferrite in the thermally aged austenitic stainless steel welds,” Scientific Report, 8: 15091, Oct. 2018.

LINK -

3

Changheui Jang*, Hun Jang, Sunghoon Hong, Jae Gon Lee, “Evaluation of the recovery of thermal aging embrittlement of CF8M cast stainless steels after reversion heat treatments,” IJPVP, Vol. 131, pp.67-74, July 2015.

LINK -

4

Hun Jang, Sunghoon Hong, Changheui Jang*, Jae Gon Lee, “The effects of reversion heat treatment on the recovery of thermal aging embrittlement of CF8M cast austenitic stainless steels,” Materials and Design, Vol. 56, pp. 517-521, April 2014.

LINK -

5

Jaeseok Park*, Minsu Kim, Byungha Chi, Changheui Jang, “Correlation of metallurgical analysis & higher harmonic ultrasound response for long term isothermally aged and crept FM steel for USC TPP turbine rotors,” NDT&E Int., Vol. 54, pp.159-165, Mar. 2013.

LINK -

6

J.S. Lee*, C.H. Jang, I.S. Kim, A. Kimura, “Embrittlement and Hardening during Thermal Aging of High Cr Oxide Dispersion Strengthened Alloys,” J. of Nuclear Materials, Vol. 367-370, pp.229-233, Aug. 2007.

LINK

-

1

Changheui Jang*, Sung Hwan Kim, Injin Sah, Daejong Kim, “Creep behavior of Alloy 617 in high temperature air and helium environments – effect of oxidation damage,” J. of Mech. Sci. Tech., Vol.30, no.10, pp.4433~4438, Oct. 2016.

LINK -

2

Ho Jung Lee, Hyunmyung Kim, Donghoon Kim, and Changheui Jang*, “Microstructure evolution of a Ni-Cr-W superalloy during long-term aging at high temperatures,” Materials Characterization, Vol. 106, pp.283-291, Aug. 2015.

LINK -

3

Ho Jung Lee, Injin Sah, Donghoon Kim, Hyunmyung Kim, Changheui Jang*, “Oxidation Characteristics of the Electron Beam Surface-Treated Alloy 617 in High Temperature Helium Environments,” J. Nuclear Materials, Vol. 456, pp.220-227, Jan. 2015.

LINK -

4

Jin Young Choi, Young Soo Kim, Hee Cheon No*, Injin Sah, Changheui Jang, “Corrosion resistance of alloys in high temperature hydrogen iodide gas environment for SI cycle,” International Journal of Hydrogen Energy, Vol. 39, no.27, pp.14557-14564, Sept. 2014.

LINK -

5

Donghoon Kim, Injin Sah, Ho Jung Lee, Sunghoon Hong, Changheui Jang*, “Development of an aluminide coating layer on Alloy 617 by Al sputtering and inter-diffusion heat treatments,” Surface and Coating Technology, Vol. 244, pp.15-22, April 2014.

LINK -

6

Injin Sah, Donghoon Kim, Ho Jung Lee, Changheui Jang*, “Development and oxidation resistance evaluation of Al-rich surface layer on Alloy 617,” Surface and Coating Technology, Vol. 236, pp.400-404, Dec. 2013.

LINK -

7

Donghoon Kim, Daejong Kim, Ho-Jung Lee, Changheui Jang*, Duk Joo Yoon, “Corrosion Characteristics of Ni-base Superalloys in High Temperature Steam with and without Hydrogen,” J. Nuclear Materials, Vol. 441, no. 1-3, pp. 612-622, Oct. 2013.

LINK -

8

Donghoon Kim, Injin Sah, Ho Jung Lee, Changheui Jang*, “Hydrogen Effects on Oxidation Behaviors of Haynes 230 in High-Temperature Steam Environments,” Solid State Ionics, Vol. 243, pp.1-7, July 2013.

LINK -

9

Injin Sah, Donghoon Kim, Ho Jung Lee, Changheui Jang*, “The recovery of tensile ductility in diffusion-bonded Ni-base alloys by post-bond heat treatments,” Materials and Design, Vol. 47, pp.581-589, May, 2013.

LINK -

10

Tae-Hyeong Kim, Dong-Hyoung Lee, Donghoon Kim, Changheui Jang and Jong-Il Yun*, “Analysis of oxidation behavior of Ni-base superalloys by laser-induced breakdown spectroscopy,” J. Anal. At. Spectrom, Vol. 27, pp.1525-1531, June 2012.

LINK -

11

Changheui Jang*, Daejong Kim, Donghoon Kim, Injin Sah, Woo-Seog Ryu, Young-Sung Yoo, “Oxidation behaviors of wrought Nickel-base superalloys in various high temperature environments,” T. of Nonferrous Metals Society of China, Vol. 21, No. 7, pp.1524-1531, July 2011.

LINK -

12

Daejong Kim, Injin Sah, Donghoon Kim, Woo-Seog Ryu, Changheui Jang*, “High Temperature Oxidation Behaviors of Alloy 617 and Haynes 230 in Impure Helium Environments,” Oxidation of Metals, Vol. 75, No. 1-2, pp.103-119, Feb. 2011.

LINK -

13

Daejong Kim, Injin Sah, Changheui Jang*, “Effects of Aging in High Temperature Helium Environments on Room Temperature Tensile Properties of Nickel-Base Superalloys,” Materials Science and Engineering - A, Vol. 528, pp.1713-1720, Jan. 2011.

LINK -

14

Daejong Kim, Injin Sah, Changheui Jang*, “Effects of High Temperature Aging in an Impure Helium Environment on Low Temperature Embrittlement of Alloy 617 and Haynes 230,” J. Nuclear Materials, Vol. 405, pp.9-16, Aug. 2010.

LINK -

15

S. K. Sharma, C. Jang, and K. J. Kang*, “Effect of thermo-mechanical processing on microstructure and creep properties of the foils of alloy 617,” J. of Nuclear Materials, Vol. 389, pp. 420-426, June 2009.

LINK -

16

Daejong Kim, Changheui Jang*, and Woo Seog Ryu, “Oxidation Characteristics and Oxide Layer Evolution of Alloy 617 and Haynes 230 at 900oC and 1100oC,” Oxidation of Metals, Vol. 71, no. 5, pp.271-293, June 2009.

LINK -

17

Changheui Jang*, Daejin Lee, and Daejong Kim, “Oxidation Behavior of an Alloy 617 in Very High-Temperature Air and Helium Environments,” Int. J. of PVP, Vol. 85/6, pp. 368-377, June 2008.

LINK

-

1

Sung Hwan Kim, Ji-Hwan Cha, Changheui Jang*, “Corrosion and creep behaviour of a Ni-base alloy in a high temperature supercritical-carbon dioxide environment,” Submitted to Corrosion Science, March 2020.

-

2

Sung Hwan Kim, Chaewon Kim, Ji-Hwan Cha, Changheui Jang*, “Corrosion behavior of Si diffusion coating on an austenitic Fe-base alloy in high temperature supercritical-carbon dioxide and steam environment,” Coatings, Vol. 10, 493, May 2020.

LINK -

3

Sung Hwan Kim, Ji-Hwan Cha, Changheui Jang*, Injin Sah, “Microstructure and tensile properties of diffusion bonded austenitic Fe-base alloys – before and after exposure to high temperature supercritical-CO2,” Metals, Vol.10, p.240, April 2020.

LINK -

4

Chaewon Kim, Ji-Hwan Cha, Sung Hwan Kim, Changheui Jang*, Tae Kyu Kim, “Development of aluminide diffusion coatings on ODS ferritic-martensitic steel for corrosion resistance in high temperature super critical-carbon dioxide environment,” Applied Surface Science, Vol.509, 145387, April 2020.

LINK -

5

Hongsheng Chen, Sung Hwan Kim, Changheui Jang*, “Effect of high-temperature supercritical CO2 exposure on the microstructure and tensile properties of diffusion-bonded Alloy 690,” J. of Materials Science, Vol.55, no.8, pp.3652-3667, Mar. 2020.

LINK -

6

Chaewon Kim, Sung Hwan Kim, Ji-Hwan Cha, Changheui Jang*, Tae Kyu Kim, “Cr diffusion coating to improve the corrosion resistance of an ODS steel in super-critical carbon dioxide environment,” Surface and Coating Technology, Vol.374, pp.66-73, Sept. 2019.

LINK -

7

Hongsheng Chen, Sung Hwan Kim, Chaewon Kim, Junjie Chen, Changheui Jang*, “Corrosion behaviors of four stainless steels with similar chromium content in supercritical carbon dioxide environment at 650 °C,” Corrosion Science, Vol.156, pp.16-31, Aug. 2019.

LINK -

8

Hongsheng Chen, Sung Hwan Kim, Chongsheng Long, Chaewon Kim, Changheui Jang*, “Oxidation behavior of high-strength FeCrAl alloys in a high-temperature supercritical carbon dioxide environment,” Progress in Natural Science: Materials International, Vol. 28, pp.731-739, Dec. 2018.

LINK -

9

Sung Hwan Kim, Gokul Obulan Subramanian, Chaewon Kim, Changheui Jang*, Keun Man Park, “Surface modification of austenitic stainless steel for corrosion resistance in high temperature supercritical-carbon dioxide environment, Surface and Coating Technology, Vol.349, pp.415-425, Sept. 2018.

LINK -

10

Gokul Obulan Subramanian, Ho Jung Lee, Sung Hwan Kim, Changheui Jang. “Corrosion and carburization behaviour of Ni-xCr binary alloys in a high temperature supercritical-carbon dioxide environment,” Oxidation of Metals, Vol 89, pp.683-697, June 2018.

LINK -

11

Ho Jung Lee, Sung Hwan Kim, Changheui Jang, “Characterization of Alloy 600 joints exposed to a high-temperature supercritical-carbon dioxide environment,” Materials Characterization, Vol.138, pp.245-254, April 2018.

LINK -

12

Ho Jung Lee, Sung Hwan Kim, Hyunmyung Kim, Changheui Jang*, “Corrosion and carburization behavior of Al-rich surface layer on Ni-base alloy in supercritical-carbon dioxide environment,” Applied Surface Science, vol. 388-A, pp.483-490, Dec. 2016.

LINK -

13

Ho Jung Lee, Gokul Obulan Subramanian, Sung Hwan Kim, Changheui Jang*, “Effect of pressure on corrosion and carburization behavior of chromia-forming heat resistant alloys in high temperature carbon dioxide environments,” Corrosion Science, Vol. 111, pp.649-658, Oct. 2016.

LINK -

14

Ho Jung Lee, Hyunmyung Kim, Sung Hwan Kim, and Changheui Jang*, “Corrosion and carburization behaviors of chromia-forming heat resistant alloys in a high temperature supercritical-carbon dioxide environment,” Corrosion Science, Vol. 99, pp.227-239, Oct. 2015.

LINK

-

1

Sung Hwan Kim, Chaewon Kim, Ji-Hwan Cha, Changheui Jang*, “Corrosion behavior of Si diffusion coating on an austenitic Fe-base alloy in high temperature supercritical-carbon dioxide and steam environment,” Coatings, Vol. 10, 493, May 2020.

LINK -

2

Chaewon Kim, Sung Hwan Kim, Ji-Hwan Cha, Changheui Jang*, and Tae Kyu Kim, “Chromium diffusion coating on an ODS ferritic-martensitic steel and its oxidation behavior in air and steam environments,” Coatings, Vol. 10, 492, May 2020.

LINK -

3

Chaewon Kim, Ji-Hwan Cha, Sung Hwan Kim, Changheui Jang*, Tae Kyu Kim, “Development of aluminide diffusion coatings on ODS ferritic-martensitic steel for corrosion resistance in high temperature super critical-carbon dioxide environment,” Applied Surface Science, Vol.509, 145387, April 2020.

LINK -

4

Chaewon Kim, Sung Hwan Kim, Ji-Hwan Cha, Changheui Jang*, Tae Kyu Kim, “Cr diffusion coating to improve the corrosion resistance of an ODS steel in super-critical carbon dioxide environment,” Surface and Coating Technology, Vol.374, pp.66-73, Sept. 2019.

LINK -

5

Chaewon Kim, Sung Hwan Kim, Gokul Obulan Subramanian, Changheui Jang*, Keun Man Park, “Integrity of alumina catalytic support prepared by anodization in a high temperature steam environment,” Metals and Materials International, Vol.25, pp.342-332, Feb. 2019.

LINK -

6

Sung Hwan Kim, Gokul Obulan Subramanian, Chaewon Kim, Changheui Jang*, Keun Man Park, “Surface modification of austenitic stainless steel for corrosion resistance in high temperature supercritical-carbon dioxide environment, Surface and Coating Technology, Vol.349, pp.415-425, Sept. 2018.

LINK -

7

Ho Jung Lee, Sung Hwan Kim, Hyunmyung Kim, Changheui Jang*, “Corrosion and carburization behavior of Al-rich surface layer on Ni-base alloy in supercritical-carbon dioxide environment,” Applied Surface Science, vol. 388-A, pp.483-490, Dec. 2016.

LINK -

8

Injin Sah, Sung Hwan Kim, and Changheui Jang*, “Microstructure and creep resistance of a Diffusionally Aluminized Ni-base Superalloy,” Metals and Materials International, Vol. 22, no.6, pp.1033-1040, Nov. 2016.

LINK -

9

Ho Jung Lee, Injin Sah, Donghoon Kim, Hyunmyung Kim, Changheui Jang*, “Oxidation Characteristics of the Electron Beam Surface-Treated Alloy 617 in High Temperature Helium Environments,” J. Nuclear Materials, Vol. 456, pp.220-227, Jan. 2015.

LINK -

10

Jin Young Choi, Young Soo Kim, Hee Cheon No*, Injin Sah, Changheui Jang, “Corrosion resistance of alloys in high temperature hydrogen iodide gas environment for SI cycle,” International Journal of Hydrogen Energy, Vol. 39, no.27, pp.14557-14564, Sept. 2014.

LINK -

11

Donghoon Kim, Injin Sah, Ho Jung Lee, Sunghoon Hong, Changheui Jang*, “Development of an aluminide coating layer on Alloy 617 by Al sputtering and inter-diffusion heat treatments,” Surface and Coating Technology, Vol. 244, pp.15-22, April 2014.

LINK -

12

Injin Sah, Donghoon Kim, Ho Jung Lee, Changheui Jang*, “Development and oxidation resistance evaluation of Al-rich surface layer on Alloy 617,” Surface and Coating Technology, Vol. 236, pp.400-404, Dec. 2013.

LINK

-

1

Sung Hwan Kim, Ji-Hwan Cha, Changheui Jang*, Injin Sah, “Microstructure and tensile properties of diffusion bonded austenitic Fe-base alloys – before and after exposure to high temperature supercritical-CO2,” Metals, Vol.10, p.240, April 2020.

LINK -

2

Hongsheng Chen, Sung Hwan Kim, Changheui Jang*, “Effect of high-temperature supercritical CO2 exposure on the microstructure and tensile properties of diffusion-bonded Alloy 690,” J. of Materials Science, Vol.55, no.8, pp.3652-3667, Mar. 2020.

LINK -

3

Ho Jung Lee, Sung Hwan Kim, Changheui Jang, “Characterization of Alloy 600 joints exposed to a high-temperature supercritical-carbon dioxide environment,” Materials Characterization, Vol.138, pp.245-254, April 2018.

LINK -

4

Injin Sah, Donghoon Kim, Ho Jung Lee, Changheui Jang*, “The recovery of tensile ductility in diffusion-bonded Ni-base alloys by post-bond heat treatments,” Materials and Design, Vol. 47, pp.581-589, May, 2013.

LINK

-

1

Hyunmyung Kim, Ho Jung Lee, Sung Hwan Kim, Changheui Jang*, “Plasma thermal performance of a dual-process PVD/PS tungsten coating structure on carbon-based panels for nuclear fusion application,” Fusion Eng. Des., Vol. 109-111, pp.590-595, Nov. 2016.

LINK -

2

Hyunmyung Kim, Ho Jung Lee, Sung Hwan Kim, Jae-Min Song, Changheui Jang*, “Performance of a dual-process PVD/PS tungsten coating structure under deuterium ion irradiation,” Fusion Eng. Des., Vol. 109-111, pp.353-358, Nov. 2016.

LINK -

3

Hyunmyung Kim, Ho Jung Lee, Changheui Jang*, “Thermal performance of multilayer PVD tungsten coating for the first wall application in nuclear fusion devices,” Fusion Science and Technology, Vol. 68, no.2, pp.378-382, Sept. 2015.

LINK